U.K. Field Trip Part 5 – Severn Valley Railway Autumn Steam Gala – Heavy Engineering

Click on each image for a closer look!

Click on each image for a closer look!

Running a railway using steam locomotives, the youngest of which are north of 60 years old (excepting 2008’s Tornado), is a very difficult and time consuming job. The Bridgnorth Motive Power Depot is the main restoration and running shed for the lines steam locomotives, and can do almost anything needed to keep a locomotive going or restore one to operation. While we were there, a Great Western Small Prairie tank No 5164 was in the shop for running repairs, with the motion disassembled to allow the Cylinders to be inspected and re-bored, during the gala the wheel drop was being demonstrated using the prairie’s centre axle. Also in the shop were parts of several locomotives undergoing full overhauls, and Dunrobin, an 0-4-4 Tank Locomotive which was repatriated from Fort Steele in BC this summer using the pallets which delivered Vicky to Canada for her role in the Railway Children.

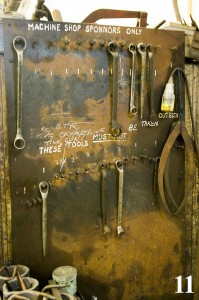

The back of the shop has a full machine shop, with a wide array of lathes, boring, milling machines, and a full wheel lathe, capable of turning the wheels of a locomotive driver back to true from the wear and tear of regular use. Also seen, was a very similar eye protection sign to those found in the Machine Shop at John Street, and re-created in the stalls by TRHA Volunteers, though it must be said that the UK version has more stylish hair than the John Street Eye Protection sign!!

Description of images:

#1 – West Country Boiler under repair

#2 -Running Repairs on the Prairie

#3 – Goggles 1

#4 – Dunrobin

#5 – Pannier 1501 Wheels

#6 – Machine Shop 1

#7 – Milling Machine

#8 – Stylish Eye Protection

#9 – Machine Shop 2

#10 – Taps

#11 – Don’t steal the tools

Click here to read the next in this series of posts.

Posting and pictures by Stephen Gardiner and Heather Meger